Mineral resources are an important material foundation for human life and production, and the degree of their development and utilization often reflects the economic development level of a country. In order to ensure the smooth progress of the mineral mining process, professional measuring instruments are essential. Through accurate measurement and planning, not only can potential risks be avoided, but also the safety of on-site personnel and mechanical equipment can be guaranteed.

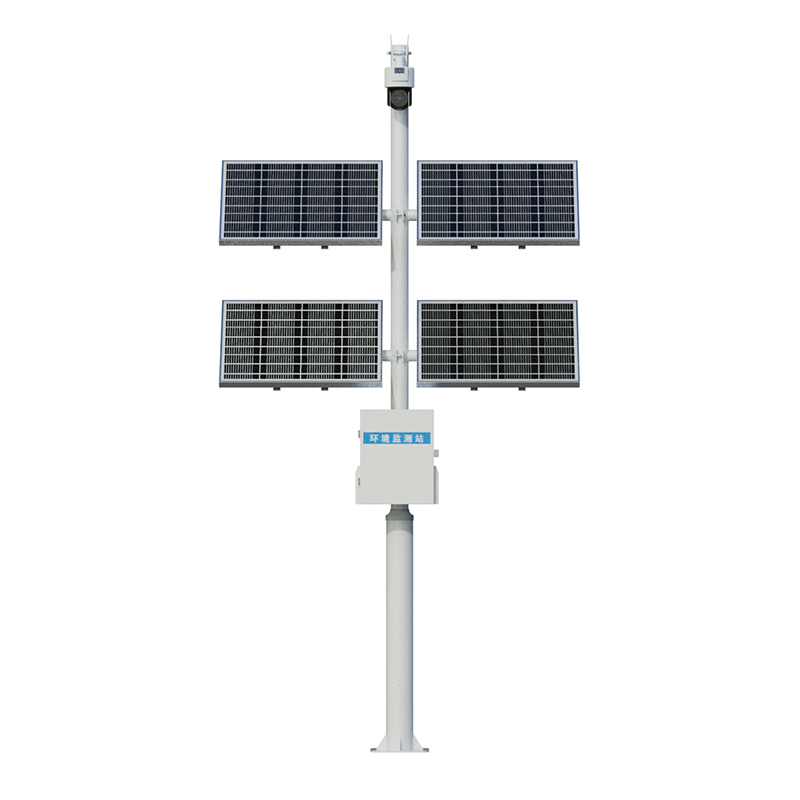

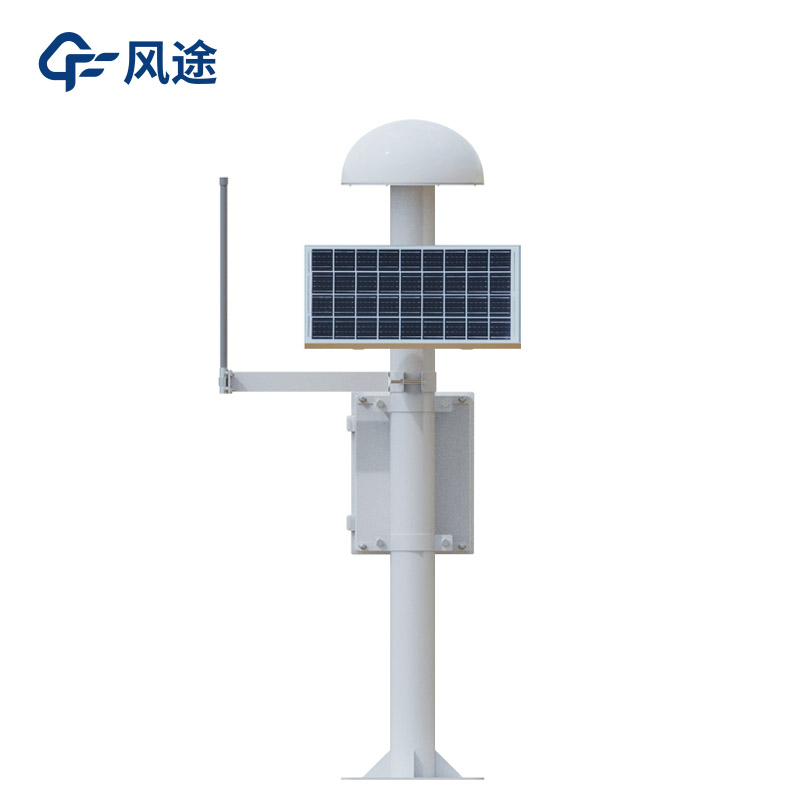

Mineral mining is a long-term project that involves the use of mechanical equipment and the construction of temporary buildings. These operations will have a profound impact on the geological environment of the mining area. Therefore, it is crucial to deploy a Surface displacement monitoring system. This device can track the horizontal and vertical displacement changes at different locations in the mining area in real time and upload the data to the environmental monitoring platform. At the same time, by establishing a surface deformation monitoring system and a surface deformation monitoring database for the mining area, strong technical support is provided for the mining process. When the stability of surface rock movement changes, the system will issue timely warnings, effectively preventing disasters and ensuring the continuous progress of mining work.

The monitoring of goafs mainly focuses on the problem of ground subsidence, which has two main causes. On the one hand, the crisscross underground roadways may lead to ground subsidence and even more serious collapses, affecting the later ground planning. Therefore, it is necessary to conduct monitoring to ensure safety before reuse. On the other hand, underground mining may induce surface deformation, which in turn affects the stability of surface buildings, industrial squares, and shafts. Comprehensive monitoring is required to fully understand its impact.

The Surface displacement monitoring system based on GNSS technology is composed of reference points, monitoring points, calculation stations or cloud platforms. It supports a distance of up to 5 kilometers between the measuring points and the reference points, and the number of measuring stations supported by the system is not limited. In practical applications, in combination with the GNSS site selection requirements, and based on factors such as the regional on-site environment and geological conditions, the monitoring grid should be reasonably divided and representative monitoring points should be selected. According to the "Technical Specification for Geological Disaster Monitoring", for the monitoring of ground subsidence in mining areas or karst ground subsidence, monitoring lines should be laid out according to the subsidence specifications and the shape of the subsidence. For areas with a small subsidence area, cross-shaped monitoring lines are advisable; for subsidence areas in the shape of a square or a circle, "Feng" (a Chinese character) - shaped or "Well" - shaped monitoring lines are more appropriate.

Through scientific monitoring and planning, GNSS technology will provide strong technical support for mineral mining!

This paper addresses:https://fengtusz.com/industry/706.html