Product Center

-

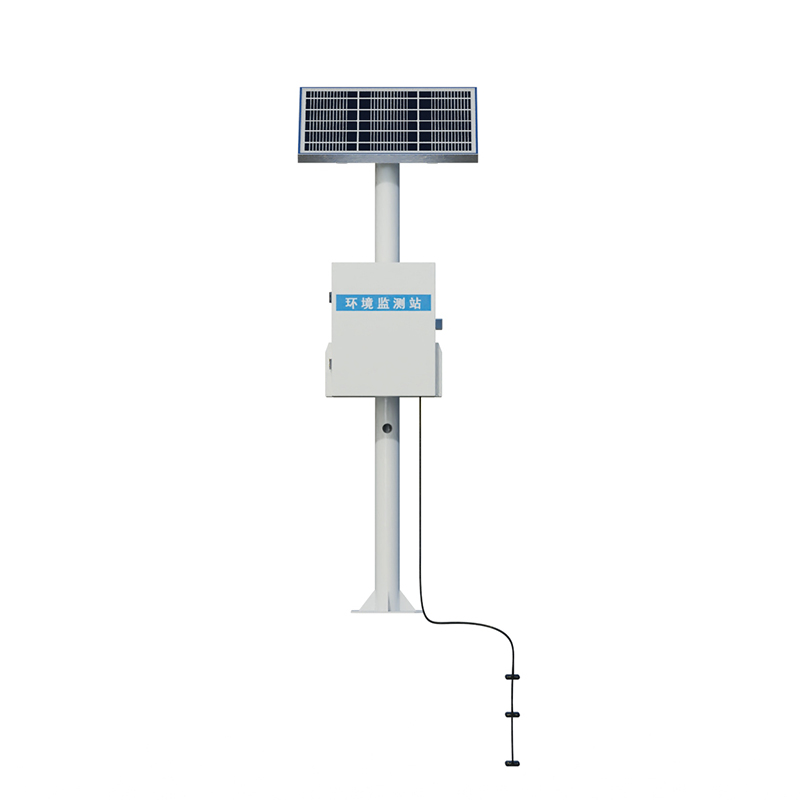

Hydrological equipment monitoring station

-

Water Quality Monitor Sensor

-

Plant protection equipment

-

Food Testing Equipment

- Radar Flow Meter Non-Contact Remote Sensing System for Open Channel Flow

- Automatic Monitoring and Identification Technology for Locusts Attracted by Light and Sex Traps

- Groundwater level monitoring equipment: Precise Measurement of Deep Well Water Levels

- Intelligent monitoring device for forest pests and diseases Accurately Captures Insect Data

- Termite Baiting Systems Real-Time Termite Activity Monitoring System

- Soil moisture monitoring station Field Rapid Deployment Monitoring of Soil Moisture, Temperature, and Electrical Conductivity

Shandong Fengtu IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Tel, Whatsapp:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

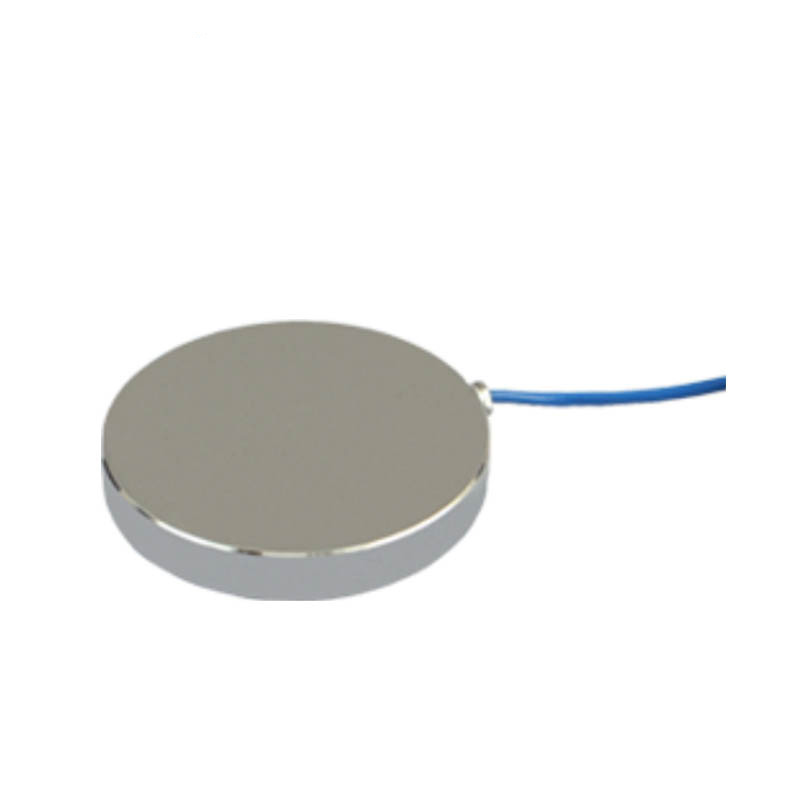

On-line ph sensor

Model:FT-S3

Brand:fengtu

Related products

Product details

1.On-line ph sensor application environment description

On-line ph sensor is a monitoring instrument for controlling pH value in water quality analysis, for environmental water quality testing, various high/low ion strength water sample testing.Used for environmental water quality testing, various high/low ionic strength water sample testing, and can meet the requirements of most industrial/environmental applications for online pH measurement.

Signal output: RS485 (MODBUS-RTU), 4-20mA current output.

Low impedance sensitive glass film, internal signal isolation technology, strong anti-interference ability.

Good reproducibility, thermal stability, low drift, small size, fast response

Easy and simple installation, 3/4NPT pipe thread, convenient for submerged installation or installation in pipes and tanks, stable performance and long service life

IP68 waterproof standard

2. On-line ph sensor technical parameters

| Measuring principle | Electrochemistry (Salt Bridge) |

| Signal method | RS485 (MODBUS-RTU) |

| Measuring range | 0~14.00(PH) |

| Measurement resolution | 0.01 |

| Measurement accuracy | ±0.1PH, ±0.1℃ |

| Response time | About 10s (98% flowing liquid) About 15s (98% stationary liquid) |

| Shell material | ABS |

| Temperature compensation | Automatic temperature compensation |

| Cable length | Standard 5 meters |

| Supply voltage | 12-24VDC (0.4W@12V) |

| Measurement environment | Temperature 0~50℃ (no freezing), < 0.2MPa |

| Waterproof grade | IP68 |

| Installation | Immersion installation, NPT3/4 thread |

3. On-line ph sensor installation and electrical connection

1. Installation

Note: The sensor cannot be installed upside down or horizontally, but must be installed at an angle of at least 15 degrees.

2. Electrical connection

The cable is a 5-core shielded cable, and the line sequence definition is:

Brown-power line (12~24VDC) Black-ground line (GND)

Green-485B Yellow-485A

The wiring sequence should be carefully checked before powering on to avoid unnecessary losses due to wiring errors.

4. On-line ph sensor maintenance and care

When using the instrument for the first time or after long-term disuse, the sensitive bulb and reference junction should be immersed in 3.3 mol/L KCl solution for more than 2 hours.

When using, it should be washed with deionized water (or distilled water) and wiped dry to prevent impurities from entering the measured liquid. 1/3 of the sensor should be inserted into the measured liquid.

The wiring terminal part should be kept clean and dry. The sensor should be cleaned when not in use and inserted into a protective cover filled with 3.3 mol/L KCI solution, or the sensor should be inserted into a container filled with 3.3 mol/L KCI solution.

Check whether the wiring terminals are dry. If there are stains, wipe them with anhydrous alcohol and continue to use them after they are dry. The sensor should avoid being immersed in deionized water, protein solution, strong acid and alkali solution, and acidic fluoride solution for a long time, and prevent contact with silicone grease. The glass membrane of the sensor that has been used for a long time may become translucent or have sediment. At this time, it can be washed with dilute hydrochloric acid and rinsed with water.

When the sensor has been used for a long time and measurement errors occur, it can be calibrated and corrected by using the instrument. If the sensor cannot be calibrated and measured after the above maintenance and care, it means that the sensor has failed. Please replace the sensor.

This paper addresses:https://fengtusz.com/Water-Quality-Sensors/On-line-ph-sensor.html

- Previous Article :Online cod turbidity sensor

- Next Article:online ammonia nitrogen sensor

Related article

-

Small automatic weather stations reduce agricultural losses

2024-03-12 -

Automatic Soil Monitoring System: Realizing Remote Real-Time Monitoring of Soil Moisture in Planting Areas

2025-09-11 -

GNSS Monitoring Station: A Reference Station for High-Precision Displacement Monitoring

2025-11-11 -

Water Quality Monitoring: Dissolved Oxygen and the Role of FT - SS04 Portable Water Quality Meter

2025-02-12 -

Farmland Weather Station: Empowering Agricultural Precision

2024-09-20 -

Three Common Life Detectors in Geological Disaster Rescue: Principles and Applications

2025-07-28 -

Environmental Flows Monitoring System: The Core of Open Channel Flow Measurement

2024-11-27 -

From Guesswork to Science: Soil Moisture Monitoring Equipment's Impact on Farming

2025-02-21

Get a Free Quote

Get a Free Quote