In the activated sludge process sewage treatment system, an appropriate sludge concentration is one of the key factors to ensure the treatment effect. If the sludge concentration is too low, it means that the number of microorganisms involved in pollutant degradation is insufficient, and organic pollutants and other contaminants in the sewage cannot be effectively decomposed, resulting in the effluent quality not meeting the standards. On the other hand, if the sludge concentration is too high, problems such as sludge bulking may occur, which also affects the treatment effect and effluent quality. By detecting the sludge concentration, the content of microorganisms in the activated sludge can be understood, so as to determine whether the sewage treatment system is in the optimal operating state and adjust the process parameters in a timely manner to ensure the effective treatment of sewage.

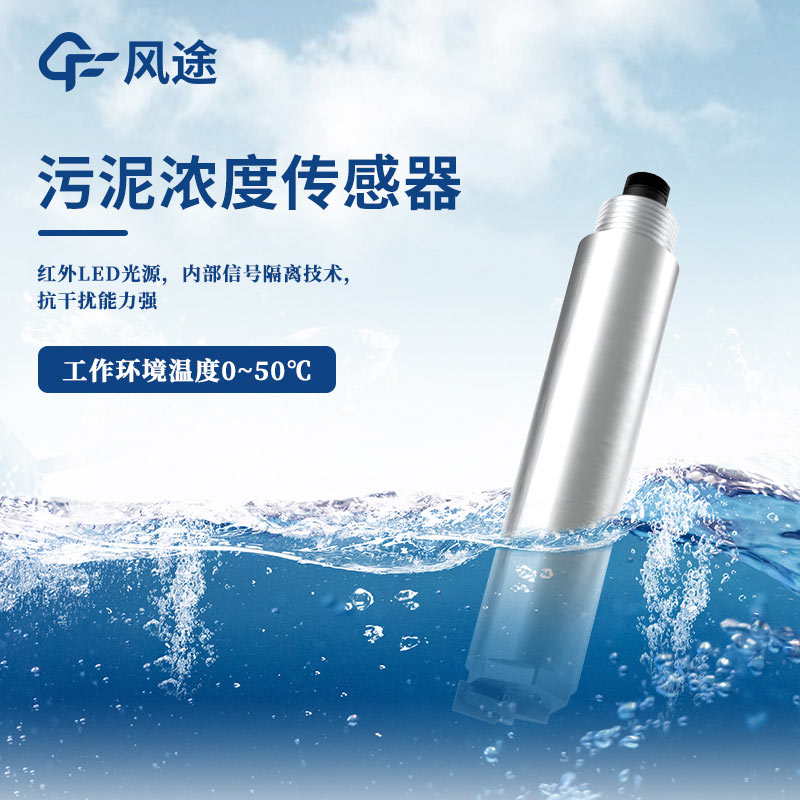

So how to detect the sludge concentration? The Sludge concentration meter is recommended.

The Sludge concentration meter based on the scattered light method utilizes the phenomenon of light scattering. When a beam of light is irradiated onto the sludge suspension, the particles in the sludge will cause the light to scatter. Under certain conditions, the intensity of the scattered light is related to the concentration and characteristics of the particles in the sludge. The sensor emits light of a specific wavelength, and then an optical detector is used to measure the intensity of the scattered light at a certain angle to the incident light. According to the corresponding relationship between the scattered light intensity and the sludge concentration, after calibration and calculation, the sludge concentration value can be obtained. Generally speaking, the higher the sludge concentration, the greater the scattered light intensity.

The Sludge concentration meter FT - S11S takes into account both practicality and convenience. It adopts a 3/4NPT pipe thread interface and supports submersible installation or direct integration into pipelines and tanks. It can adapt to the complex working conditions in sewage treatment plants and greatly reduce the installation and maintenance costs. In addition, the sensor has stable performance and a long service life, reducing the need for frequent calibration or replacement. Combined with the real - time monitoring function, it can replace manual sampling, which not only avoids errors but also improves the level of automated management.

This paper addresses:https://fengtusz.com/industry/687.html