The installation of the Soil Moisture Sensor requires comprehensive consideration of the placement location and installation method to ensure accurate measurement of soil moisture conditions.

Regarding the sensor placement location, it should be placed at different depths and locations in the field. Generally, they are placed in pairs at one - third and two - thirds of the depth of the crop root zone, and two or more locations are selected in the field. These locations are preferably in representative soil types and away from high points, depressions, and slopes, so that the overall soil moisture in the field can be more accurately reflected.

For fields containing both heavy - textured and light - textured soils, it is recommended to use on - site mapping techniques, such as electromagnetic conductivity mapping, to identify different soil types because different soils have different water - holding capacities. Through this identification, each soil type can be monitored and irrigation - managed separately, thus creating individually manageable areas.

When placing fixed sensors, they should be placed at the required depth between plants within the crop row, and marked clearly so that on - site equipment operators can see them clearly to avoid damaging the sensors during operations.

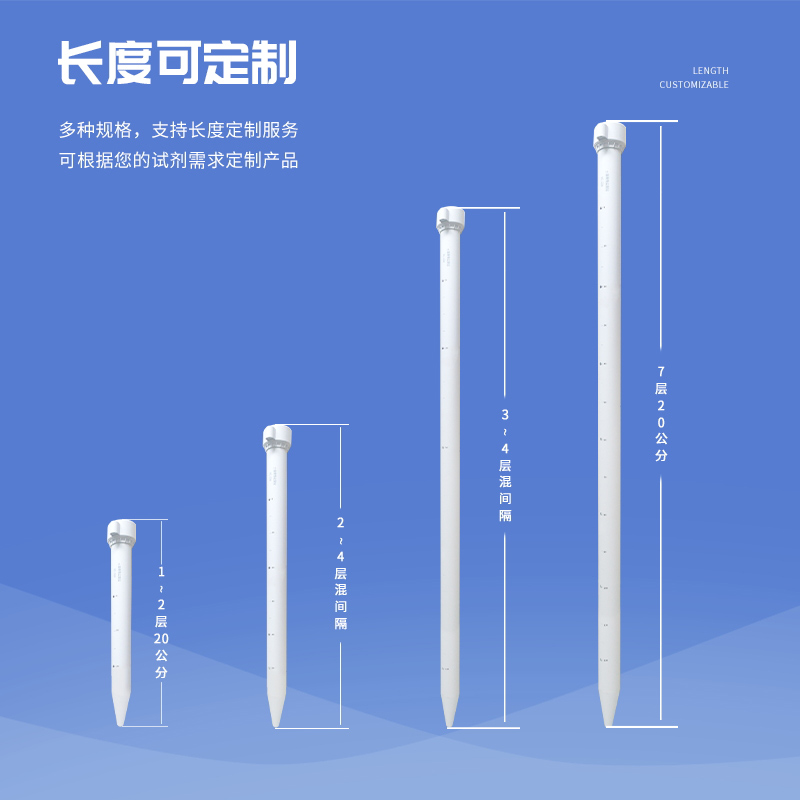

In terms of the installation method, it should be carried out according to the design of the sensor, strictly following the installation instructions provided by the manufacturer. Usually, there are two common installation methods for soil moisture sensors. One is to dig holes or trenches and then install the sensors horizontally at different depths; the other is to drill holes using an auger or a soil sampling probe and then install the sensors vertically. Extra care must be taken when drilling holes. Holes that are too large should not be drilled, as voids and air gaps can easily form, which will affect the accuracy of the sensor's measurement.

Although some users use a mixture of soil and water (soil slurry) during installation to prevent air gaps, in many cases, the structure of the slurry does not match the surrounding soil and may have an adverse effect on the sensor readings. Therefore, during the installation process, appropriate installation methods and attention to details should be carefully selected to ensure the normal operation of the Soil Moisture Sensor.

This paper addresses:https://fengtusz.com/industry/524.html