Product Center

-

Hydrological equipment monitoring station

-

Water Quality Monitor Sensor

-

Plant protection equipment

-

Food Testing Equipment

- From Guesswork to Science: Soil Moisture Monitoring Equipment's Impact on Farming

- The Advantages and Wide Applications of Water Level Monitoring Station in Water Level Measurement

- Combatting Potato Late Blight with the Intelligent Potato Late Blight Monitor

- Online Ammonia - Nitrogen Sensors: Pivotal Tools in Understanding, Measuring and Solving Ammonia - Nitrogen Issues

- Cultivate Success with the Soil Temperature and Moisture Meter

- Water Quality Monitoring System: Detecting Pollutants, Ensuring Safety

Shandong Fengtu IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Tel, Whatsapp:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

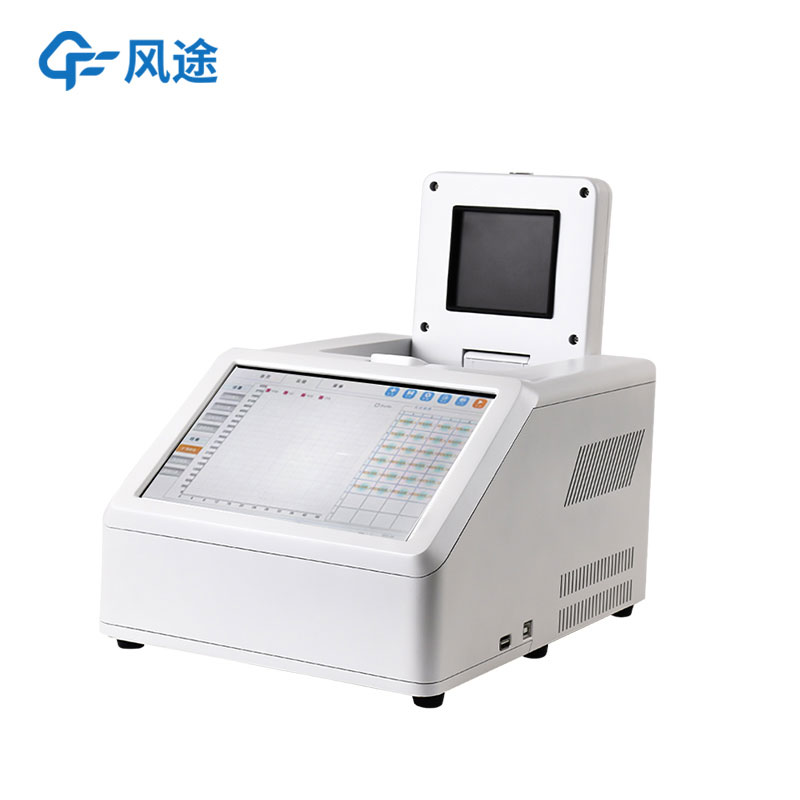

Media Monitoring

Model:FT-DT1

Brand:fengtu

Related products

Product details

1.Media Monitoring Background

Media Monitoring is used to monitor the environment of subway projects and the possible deformation of surface and underground structures during construction.The subway is like an oxygen supplier for modern cities, supplying power and energy for the continuous development of the city. It can not only create wealth and business opportunities, but also lead the change of people's living lifestyle and create an era of subway cities. In recent years, subway accidents have continued to occur, and the total number of casualties has begun to increase significantly, with the curve showing a clear upward trend. The accidents reflect the insufficiency of safe construction monitoring technology and means, as well as the lack of construction safety management and supervision. The high technology content and high risk in subway construction all require a strong sense of safety, careful safety management and strict safety supervision to achieve. The subway project is largely a project that tests safety management. In order to keep abreast of the status of subway construction, give early warning of emergencies, maintain the safety of subway construction and social stability, and prevent tragedies like the Hangzhou subway collapse from happening again, the safety of subway construction is imminent.

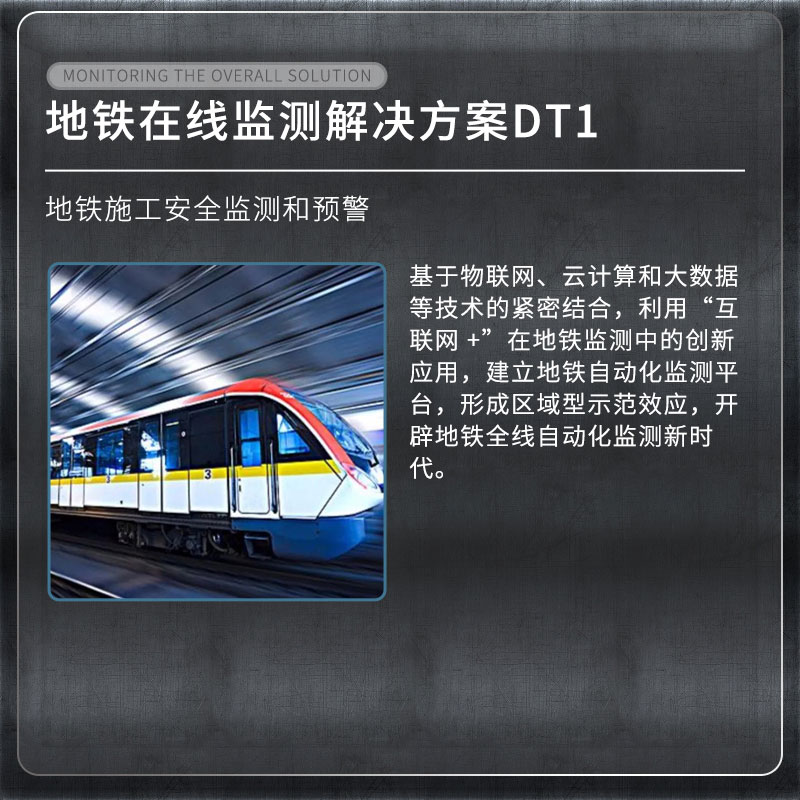

2. Media Monitoring System Overview

Based on the close integration of technologies such as the Internet of Things, cloud computing and big data, and utilizing the innovative application of Internet+ in subway monitoring, a subway automated monitoring platform will be established to form a regional demonstration effect and open up a new era of automated monitoring of the entire subway line.

3. Main monitoring contents of Media Monitoring

1. Subway foundation pit: settlement and horizontal displacement of top of retaining piles (walls), deep horizontal displacement of retaining piles (walls), internal force of retaining piles (walls), deep horizontal displacement of soil outside the pit, axial force of anchor rods, groundwater level, axial force of support, uplift of pit bottom

2. Subway tunnel:

① Shield method: segment clearance convergence, segment structural stress

② Mining method: vault settlement and convergence, blasting vibration, vertical displacement of the center column structure, groundwater level

3. Surrounding risk sources: surface settlement, pipeline settlement, building tilt, uneven building settlement, building cracks, bridge pier tilt, uneven bridge pier settlement

IV. Media Monitoring Project List

| Monitoring items | Device Name | Monitoring items | Device Name |

| Support shaft force | Strain gauges, force gauges | Vertical displacement of buildings (structures) | Static Level |

| Vertical displacement of bridge piers | Fully automatic robot | Building (structure) cracks | Crack meter |

| Bridge pier tilt | Box type fixed inclinometer | Vertical displacement of segment structure | Laser rangefinder |

| Bridge cracks | Crack meter | Segment structure clearance convergence | Laser rangefinder |

| Anchor bolt axial force | Steel bar meter | Vertical displacement of underground pipelines | Fully automatic robot |

| Groundwater level | Pore water pressure gauge | Vertical displacement of column structure | Fully automatic robot |

5. Media Monitoring Basis

"Technical Specifications for Construction Monitoring of Urban Rail Transit Projects DG/TJ 08-2224-2017"

"Technical Specifications for Urban Rail Transit Engineering Monitoring GB50911-2013"

"Technical Specifications for Construction Foundation Pit Engineering Monitoring GB 50497-2009"

"Urban Rail Transit Engineering Survey Specification GBT50308-2017"

6. Media Monitoring Implementation Function

1. Online monitoring of subways during construction: Compare monitoring data with design values to determine whether construction technology and construction parameters meet expected requirements, predict possible dangers in advance and take necessary engineering measures to ensure smooth progress of the project and ensure construction quality and safety.

2. Online monitoring of subways during operation: Continuous and accurate monitoring of horizontal and vertical displacement of sections is achieved, so as to understand the deformation characteristics and laws of sections during operation and achieve the purpose of information monitoring. When the change value exceeds the preset value, an early warning can be issued in time.

本文地址:https://fengtusz.com/Geological-Disaster-Monitor/Media-Monitoring.html

- Previous Article :Slope monitoring

- Next Article:Foundation pit monitoring

Related article

-

Flexible Soil Moisture Monitoring Stations: Tailored for Agricultural Diversity

2025-01-16 -

Wheat Armyworm Monitor: Empowering Farmers with Precise Pest Data

2024-12-31 -

Agri-weather stations are important

2024-03-22 -

Water quality monitoring stations to protect lake resources

2024-06-19 -

What is drainage network monitoring equipment?

2024-03-21 -

Drainage Pipeline Monitoring with FT - PS1

2025-01-13 -

Rodent Intelligent Cyclic Trap and Control Device

2024-05-16 -

Small weather stations in agriculture: an indispensable tool for modern agricultural management and scientific research

2024-04-08

Get a Free Quote

Get a Free Quote