Product Center

-

Hydrological equipment monitoring station

-

Water Quality Monitor Sensor

-

Plant protection equipment

-

Food Testing Equipment

- Radar Flow Meter Non-Contact Remote Sensing System for Open Channel Flow

- Automatic Monitoring and Identification Technology for Locusts Attracted by Light and Sex Traps

- Groundwater level monitoring equipment: Precise Measurement of Deep Well Water Levels

- Intelligent monitoring device for forest pests and diseases Accurately Captures Insect Data

- Termite Baiting Systems Real-Time Termite Activity Monitoring System

- Soil moisture monitoring station Field Rapid Deployment Monitoring of Soil Moisture, Temperature, and Electrical Conductivity

Shandong Fengtu IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Tel, Whatsapp:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

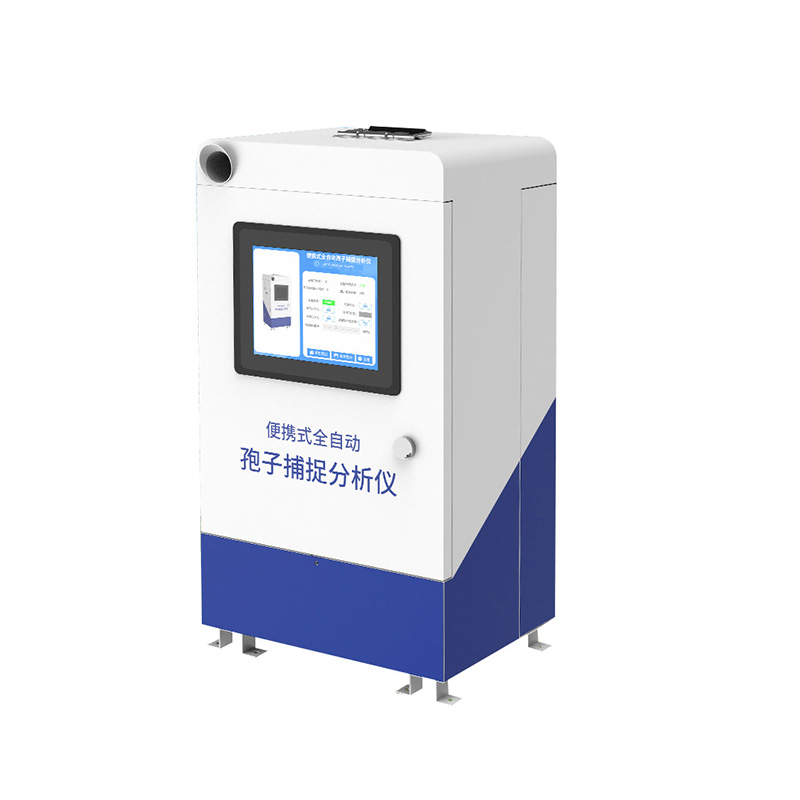

Water Blue Green Algae Sensor

Model:FT-S16S

Brand:fengtu

Related products

Product details

one.Water Blue Green Algae Sensor application environment description

Water Blue Green Algae Sensor uses the absorption and reflection of specific wavelength light to monitor the concentration of blue-green algae.Utilizing the fluorescence excitation characteristics of phycocyanin in blue-green algae, the concentration of blue-green algae can be measured by emitting a beam of a specific wavelength to excite phycocyanin and then detecting the intensity of its excited fluorescence.It has high sensitivity, fast response and real-time monitoring capabilities, and is widely used in water quality monitoring and other fields.

Signal output: RS485 (MODBUS-RTU).

Filter detection, strong anti-interference ability.

Internal signal isolation technology, strong interference resistance.

Good reproducibility, thermal stability, low drift, small size, fast response

Easy and simple installation, 3/4NPT pipe thread, convenient for submersible installation or installation in pipes and tanks

Stable performance and long service life

IP68 waterproof standard

two.Water Blue Green Algae Sensor technical performance and specifications

1.Technical parameters

| Measurement principle | Fluorescence method |

| Signal mode | RS485 (MODBUS-RTU) |

| Measuring range | 0~200.0Kcells/mL |

| detection limit | 1.0Kcells/mL |

| linearity | R²>0.999 |

| Measurement resolution | 0.1Kcells/mL |

| Shell material | Glass, 316L stainless steel, ABS plastic |

| Cable length | Standard 5 meters |

| Supply voltage | 12-24VDC (0.4W@12V) |

| Calibration method | Two point calibration |

| Measurement environment | Temperature 0~50℃ (non-freezing), <0.2MPa |

| Waterproof level | IP68 |

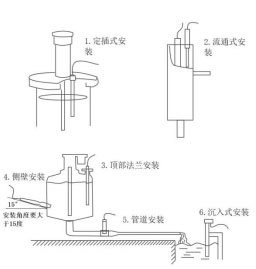

| Installation method | Submersible installation, NPT3/4 thread |

| Self-cleaning function | Equipped with an automatic cleaner to prevent biological adhesion and light window pollution to ensure long-term monitoring stability; the automatic cleaning time and cleaning frequency can be set, and the power consumption is 0.7W |

The sensor connector is M12 aviation plug connector 5-pin female seat

three.Water Blue Green Algae Sensor Installation and Electrical Connections

1.Installation

Installation distance requirements: keep more than 5cm from the side wall and more than 10cm from the bottom.

Installation environment: Do not work under strong light, try to work in a dark environment.There cannot be other fluorescent substances that can be excited.

2.Electrical installation

The cable is a 4-core shielded wire, and the wire sequence is defined as:

Red - power cord (12~24VDC)

Blue - Ground (GND)

Green-485B

Yellow-485A

The wiring sequence should be carefully checked before powering on to avoid unnecessary losses caused by wiring errors.

Note: The color of the cable may vary slightly due to different production batches, please refer to the silk screen printing of the cable.

Four.Water Blue Green Algae Sensor care and maintenance

1.Use and maintenance

The measurement window of the sensor is one of the key components to ensure the normal operation and accurate measurement of the sensor.Its cleaning requirements are critical to ensure accuracy and reliability of measurements.

1.1 Maintenance methods

1.Regular cleaning: The measurement window should be cleaned regularly to remove dirt, sediment and other impurities attached to the surface.The frequency of cleaning depends on the measurement environment, but daily or weekly cleaning is generally recommended.

2.Use mild cleaners: When cleaning, you should choose mild cleaners and avoid using cleaners containing abrasives or acid-base ingredients to prevent damage to the surface of the measurement window.

3.Soft cloth or sponge: During the cleaning process, a soft cloth or sponge should be used to gently wipe the surface of the measurement window to prevent scratches or wear.

4.Avoid direct contact: Avoid direct hand contact with the surface of the measurement window during the cleaning process to reduce fingerprint and grease contamination.

5.Rinsing: After cleaning is completed, the measurement window should be rinsed thoroughly with clean water to ensure that residual detergent and dirt are removed.

6.Drying: After cleaning, use a dry soft cloth to gently wipe the surface of the measurement window to remove water stains and ensure complete dryness.

7.Regular inspection: Regularly check whether the surface of the measurement window is damaged or worn to maintain the normal operation of the sensor.

8.Avoid exposure to chemicals and high temperature environments: Avoid exposing the measurement window to harmful chemicals or high temperature environments to prevent damage or corrosion to its surface

When the sensor has been used for a long time and measurement errors occur, it can be calibrated and corrected by cooperating with the instrument.If the sensor cannot be calibrated and measured after maintenance and maintenance in the above way, it means that the sensor has failed.Please replace the sensor.

1.2 Precautions

1.The measurement window contains glass components, so avoid using sharp or hard objects to scratch the surface to prevent scratches and damage.

2.It contains sensitive optical components and precision electronic equipment.Avoid exposing the sensor to severe vibration or impact to prevent the optical parts and electronic equipment from being displaced or damaged.There is no maintenance required inside the device.

3.When not in use, an appropriate dust cover or sleeve should be used to protect the optics from dust and contaminants.

This paper addresses:https://fengtusz.com/Water-Quality-Sensors/Water-Blue-Green-Algae-Sensor.html

- Previous Article :Salinity sensor

- Next Article:Oil in Water Analyzer

Related article

-

The Role of Water Level Monitoring System in River and Reservoir Flood Prevention

2025-08-13 -

From Data to Action: How Soil Moisture Testing Equipment Optimizes Agricultural Water Use

2025-07-25 -

Flexible Soil Moisture Monitoring Stations: Tailored for Agricultural Diversity

2025-01-16 -

The Significance and Function of Handheld Weather meter in the Wild

2025-03-17 -

Design plan for a river channel sewage discharge and water quality monitoring system platform

2026-02-02 -

Which is the best integrated water and fertilizer system?

2024-08-22 -

FT-HC1 Locust Online Monitoring Station: A Powerful Tool for Locust Observation and Control

2024-10-21 -

Smart Water Quality Monitor

2024-08-15

Get a Free Quote

Get a Free Quote